Matsumoto Yushi Seiyaku Co., Ltd manufactures and markets fibre and textile chemicals, Micorcapsules, all types of surfactants, and high polymer based products.

HOME > Products:General Industry related > Matsumoto Microsphere®F and FN series

Product Name

[Thermo-expandable microcapsule (Product Name: Matsumoto Microsphere®F and FN Series)]

Outline

Matsumoto Microsphere®F and FN series are microcapsules of thermoplastic resin whose high polymer forms the shell material. The shell contains a low boiling point liquid hydrocarbon which is trapped (encapsulated) inside it.

On heating such a microcapsule, rising temperature will induce two transformations. One is the softening of shell material while the other is the gasification of the hydrocarbon liquid inside it. With both changes happening almost simultaneously, as a result the shell will expand as the increased inner pressure pushes the softened shell wall from inside out producing a remarkable growth in size. The volume can grow 50 to 100 times larger after expansion which makes that somehow analogous to a table-tennis ball growing into a basket ball in size.

With such unique characteristics Matsumoto Microsphere®F and FN series are generically called thermo-expandable microcapsule and are widely used in many industrial fields.

Structure and expansion mechanism of Matsumoto Microsphere®F and FN series

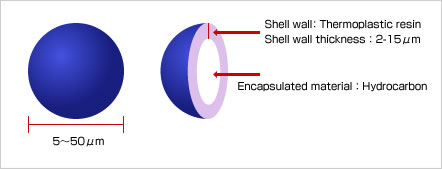

Matsumoto Microsphere®F and FN series and which are thermo-expandable have an average particle size of 5 to 50㎛.

As illustrated in schematic diagram no.1, shell wall thickness of microcapsule ranges from 2 to 15㎛. The diagram shows a cross sectional view of the microcapsule illustrating the shell wall and the hydrocarbon encapsulated inside it. The hydrocarbon gas works as a blowing agent.

The microcapsule can stand up to 300 kg/cm2 of mechanical pressure and is solvent resistant.

Storage: Microsphere®F and FN series must be stored indoors where temperature does not exceed 40DC so that the product maintains its stability.

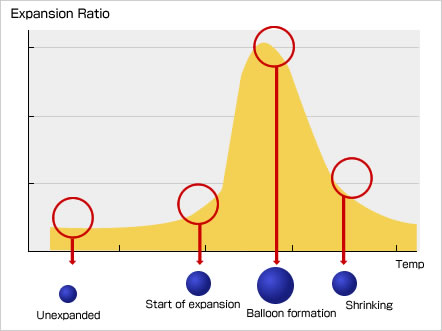

Expansion Mechanism

On heating thermo-expandable microcapsules, first their shell starts softening. Simultaneously almost, the encapsulated hydrocarbon liquid starts gasifying and, as a consequence, inner pressure of shell rises leading to the inflation of microcapsule thus announcing the start of expansion.

In this process of expansion, and as long as the balance between inner pressure, shell polymer tension and outer pressure is maintained, balloon expansion is also maintained. As heating is further prolonged, and as a result of which shell has been further softened, the gas inside the shell permeates the thinned shell wall and diffuses into the air. This happens when inner pressure is outperformed by both outer pressure and shell tension, thus breaking the balance and causing the expanded balloon to shrink. Nevertheless, a shrinking balloon does not mean that it has burst out. The balloon shell is resilient enough to sustain this change without collapsing.

Since the market launch of Matsumoto Microsphere®F, and in no time sensing the functional capabilities due this expansion property of microcapsule, we have proactively developed expanded versions of the product. These are far lighter than conventional filler materials with unique physical properties. This has made expanded plastic microballoon also available to the market in commercial quantities.

Matsumoto Microsphere®F-E (Expanded version : Wet type)

Matsumoto Microsphere®F-E is the expanded version of Matsumoto Micrsphere®F and FN series and is available as plastic microballoon with true density ranging between 0.02 and 0.05. The product is supplied in wet form having 90% water content. Being in wet form offers to customers the clear advantage of a dust-free working environment and easy handling operation of the plastic microballoon.

Matsumoto Microsphere®F-DE (Expanded version : Dry type)

Matsumoto Microsphere®F-DE is the expanded version of Matsumoto Microsphere®F and FN series and is available as plastic microballoon with true density ranging between 0.02 and 0.05. The product is supplied in dry from having 98% solid content. It is indeed dry powder, but it is ultra light and highly fluid

Click here for viewing product data

Applications

- Three dimensional design: Braille paper for those with vision disability, three dimensional maps, wall paper, t-shirts

- Anti-slip coating: cardboard, carpet backing

- Weight reducing, bulk improving, and volume producing: Non-woven material, paper, synthetic wood

- Protective layer forming (by cushioning effect): Automotive underbody coating, automotive interior trims and lining

- Internal additive: cable filling, tires and rubber goods

- Weight reducing: Paper, cones of stereophonic sound systems

- Pore formation: Artificial leather

- Adhesives: Masking tape, sealants

- Weight reducing: Paints, synthetic paper, structural materials, resins, rubber goods

- Protective layer forming (by cushioning) and bulk improving: Paints, automotive underbody coating, sealants

- Sensitivity improver: Slurry explosives

- Pore formation: Ceramics, batteries

- Masking agent: Paints

- Thermal insulation: construction material